What Is Concrete Formwork?

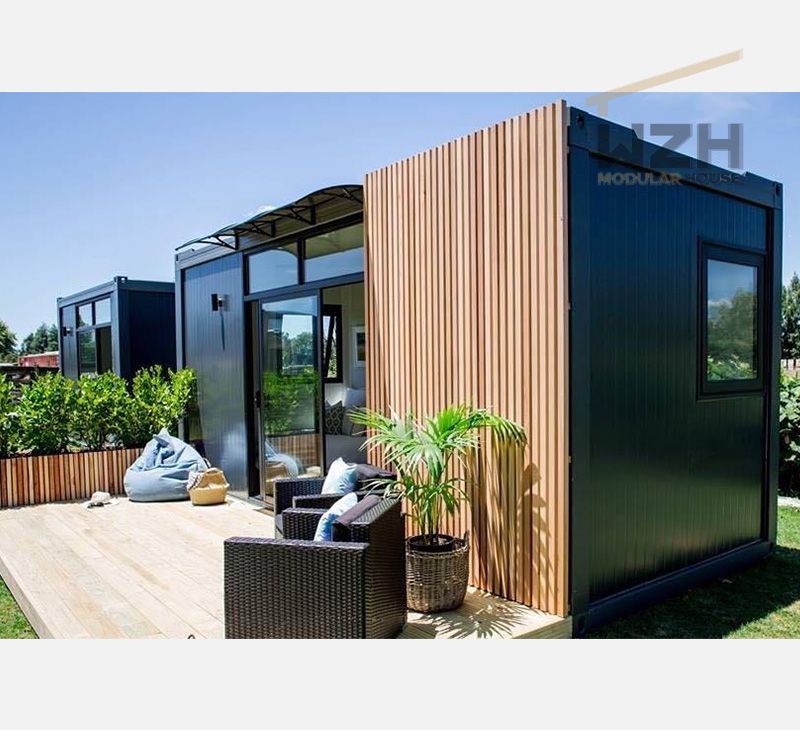

Concrete formwork is a mold or frame that holds wet concrete (poured into the formwork) until it dries and creates the desired structure that suits the purposes of a construction project. Concrete formwork can be temporary or permanent. When it is temporary, it is removed once the concrete sets. Temporary formwork is more common than permanent formwork. It can be re-used for other projects once it is no longer needed, which is of great benefit to the contractor. Because of this, temporary formwork can be resold after a project or reused on a later job. Temporary concrete formwork can be made of heavy-duty aluminum, steel, plastic, plywood, or timber. Permanent formwork, which remains in place and becomes a part of the construction after the concrete sets is often made of foam material.

The process of using concrete formwork in construction is sometimes referred to as “shuttering.” A major benefit of using concrete formwork is that it aids in achieving a desired concrete shape with a great degree of precision. Use of formwork as opposed to other methods of setting concrete is quick and efficient.

Concrete Formwork Projects

Below are some of the types of projects in which concrete formwork is used:

-

Building construction (residential, commercial, skyscrapers, airports, high rises, etc.)

-

Bridge construction

-

Highway construction

-

Overpass construction

-

Industrial and energy construction

-

Viaduct construction

-

Tunnel construction

-

Wastewater treatment plant construction

-

And more!

Formwork has been a vital component of architecture projects since its use in Ancient Rome to help construct monuments like the Pantheon and the Colosseum. Its longevity in construction is due to its usefulness and reliability.

Styles and Types of Formwork

Formwork comes in various shapes, sizes, and styles to suit the needs of individual projects. Column forms, box culvert forms, and bridge overhang brackets are all popular styles. In addition to coming in different styles, there are various types of formwork classified based on their materials as well as their uses. Below are some of the most popular types of formwork:

-

Engineered formwork systems – These are prefabricated structures with metal frames (typically aluminum or steel). They are quick to install and use and easy to remove once concrete sets. Plus, they are durable, which means they can be re-used and re-purposed for several other projects.

Featured content:

Differences Between Pipe Joints And Pipe Fittings

How do you fix loose mosaic tiles?

Is Birch plywood good for laser cutting?

Choosing the Right Faucet for Hospitals: A Comprehensive Guide

What are L shaped anchor bolts used for?

Are there different types of Geotextiles for specific applications?

What are the types of cleanroom walls? -

Timber formwork – This is a popular choice. Installation can take a bit longer than it does with steel or aluminum formwork, and timber is less durable so it can’t be re-used for a great number of projects without degrading to the point that it’s no longer viable.

-

Permanent insulated formwork – This is the most common type of permanent formwork. As mentioned previously, it’s usually made of foam and remains in place once concrete sets. A benefit of using this kind of formwork is that it can improve the thermal conditions of a structure, i.e. keep a building better insulated from changes in outside temperature.

-

Plastic formwork – These are modular and interlocking structures that can easily be built to size and desired shape and removed when the time comes. They are a good choice for mass housing projects that require low costs and simple concrete formwork systems.

-

Stay-in-place formwork – Made of plastic and easily installed on site, this type of formwork is often used for column applications and pier construction. It’s a permanent type of formwork than can reinforce the strength of concrete structures.

The best type of formwork or style of formwork for a project will hinge upon its particular needs. Overall, concrete formwork is a smart addition to numerous kinds of construction projects and will remain a staple in the construction industry for the foreseeable future.

Interested in learning more about concrete formwork? Read one of our most popular blogs, titled “How Long Should You Wait to Remove Concrete Formwork?”

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading was created to give contractors a platform for buying and selling new, used, and surplus heavy civil materials and equipment. Our concrete equipment inventory ranges from concrete formwork, to bridge deck finishers, and everything in between. Furthermore, our material inventory includes used HDPE pipe, used crane mats, used barrier wall, and much more.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.

Formwork for Concrete

Definition: total system of support for freshly placed concrete including the mold or sheathing that contacts the concrete as well as supporting members, hardware, and necessary bracing (also called shuttering in the United Kingdom).- ACI Concrete Terminology

Formwork molds the concrete to the desired size and shape, and controls its position and alignment. It is a temporary structure that supports its own weight and the freshly placed concrete, as well as construction live loads including materials, equipment, and workers.

What Is Concrete Formwork?

Formwork for Concrete Topic

Featured content:How does a water gate flood barrier work?

How to build plywood shelves?

What are the three types of vinyl flooring?

How often should cooling tower fill be replaced?

Applications and Properties of Hydroxypropylmethylcellulose (HPMC)

How do you fix loose mosaic tiles?

What type of mosaic is best for swimming pools?